Tool Monitoring System

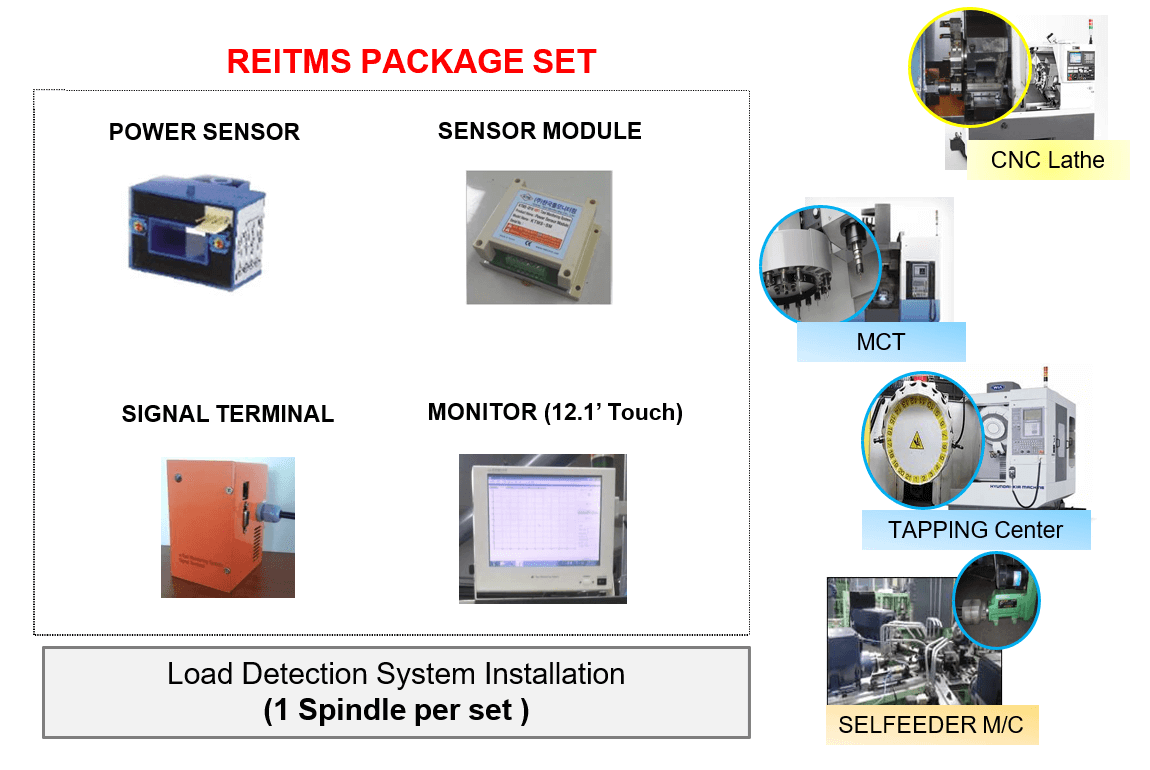

REITMS-2020

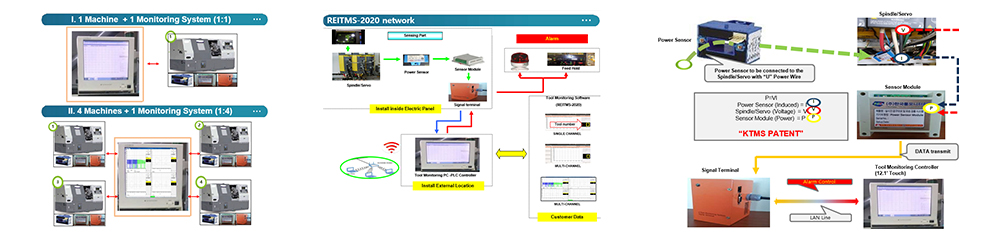

- Direct detection using a high-precision sensor ; not indirect calculation using “NC data”

- No interference of the Cycle Time ; “Zero” in loss time.

- Unlimited detection by the number of tools attached to the machine; Monitoring per axis.

- Up to 12 machines tools can be monitored with 1(one) monitoring PC at the same time.

- Condition : For each machine there must be a (sensor module + signal terminal) installed.

- Detection can be over Ø 0.38 drill ;

- The world’s first aluminum material : M3.5 roll-tap damage detection successfully

- Various Conditions for “Machine Stop” if to meet limit condition ;

Monitoring Program

Quality Certification

- Reasonable Price - Most Companies have a ROI in at least in 3 months.

- Three (3) version by function -economy, standard & premium will save customers money.

- In cases of abnormal operation, an alarm is activated to signal the use of the tool monitoring system

- At all times this system is used for – Compulsory Function of Production Management!

- Two(2) domestic patents – PAT. Nr. 10-0952619 & ISO 9001 acquisition.

- Diversification of sale overseas- US, China and Taiwan, India, Mexico, Japan & Poland

- Registered the top auto-supplier & machine maker

Aimed at the Administrator

Aimed at the Administrator / Top-Manager for Cost Control of Tooling

- Automatic DB storage – black box function - in the tool monitoring s/w file.

- Monitor if Functioning, Non-Running, Time of Cycle and Cause of Errors.

- Automatic 30days data saving –USB output

- Use FTP S/W for tool monitoring(REITMS), data can be downloaded to the network system Server.

- Tool Trend, Alarm History Management and Analysis of Data Provided.

Aim at the operator

- Realization of quality management - exclusive tool monitoring display(12.1 inch touch screen).

- Easy operator identification - a separated warning light occurs based on the condition.

- Simple operation (5 min. of basic training to understand the system).

- Software worldwide language support.

- Optimized “Linux”(OS cost zero operating). If necessary WINDOW OS is possible.