Press Technology

Center Master

Self Aligning & Correction Devices

CENTER MASTER

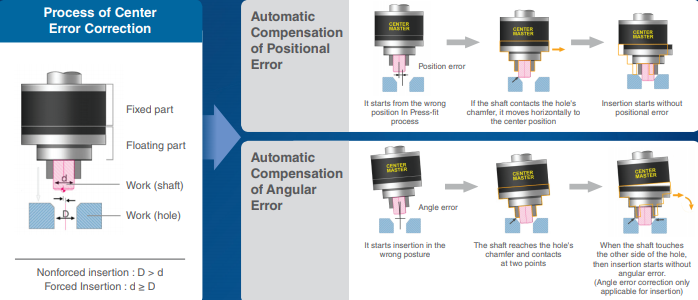

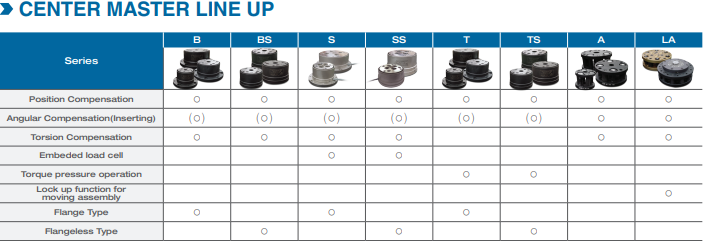

Our exclusive Center Master devices compensate for positional and/or angular errors, which are major contributors to poor press-fit, machine and tooling wear, machine and tooling failure, and poor quality.

Download Product Catalog

Download Product Catalog

AC Servo Press (FlexPress) EM/SEM

AC Servo Press

FlexPress EM/SEM

The FlexPress EM/SEM – Series is precisely driven by an AC Servo motor and an elaborate ball screw system. The FlexPress is a cost effective way to press-fit bearings, oil seals, bushings, pins, shafts, gears, etc. It is also used for riveting, stamping, forming, bending, injecting, etc.

Download Product Catalog

Download Product CatalogPrecision

- Repeatability: +/- 0.01mm

- Min. Position Setting: 0.001mm

- Force Setting: < 0.5% of F.S.

Various Models

- Max Thrust: 2kN-100kN (Stock)

- Custom: 150, 200, 300, and 500kN

- Speed: 83.3mm/s – 185.2mm/s

- Stroke: 150 – 400mm

- C&M or Allen-Bradley Motor/Other

Monitoring Program

- Real-time quality management

- Intuitive interface for user friendly operation

- Superior data analysis functions to effectively manage quality

- Detect critical point, load at assigned locations, contact point, etc.

Bench Servo Press (FlexPress BEM)

Bench Servo Press

FlexPress BEM

The FlexPress BEM – Series is a bench top servo press ideal for lower volume batch production lines where a fully automated system may be excessive. This series allows you to control each of your products under optimal conditions.

Download Product Catalog

Download Product CatalogPrecision

- Repeatability: +/- 0.01mm

- Min. Position Setting: 0.001mm

- Pressing Force Set Unit: 10N

Reduced Investment

- Cost Effective

- Low Operating & Maintenance Costs

User Convenience

- Easy Installation

- Basic Movements From Panel

- Easy Teaching Through Jog

- Wide Screen & Graphic Interface

- Additional Sensors for Safety

Systematic Management

- Manages Up to 100 Production Models

- Optimized Operation for Each Process

- Various Determination Conditions, Pass/Fail

- Superior Data Analysis